1953 - 2023 da 70 anni ci occupiamo di molle di precisione

1953 - 2023 da 70 anni ci occupiamo di molle di precisione

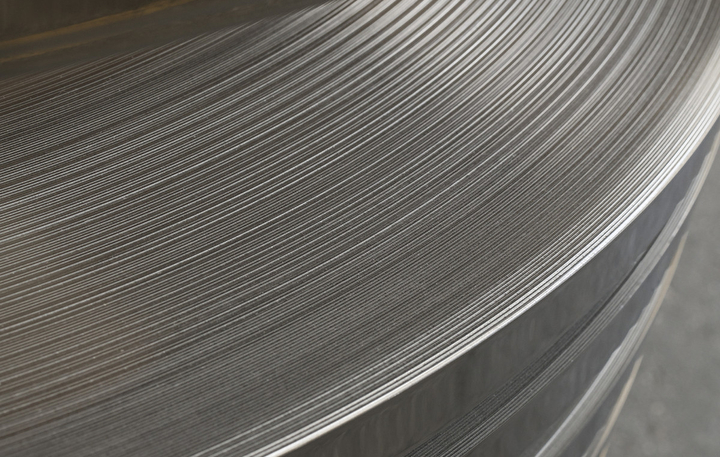

In-depth constant checks starting from the incoming material. Through sampling plans, chemical analysis tests, identification of the casting of each individual coil Mollificio Mantovano guarantees complete compliance of the raw materials used.

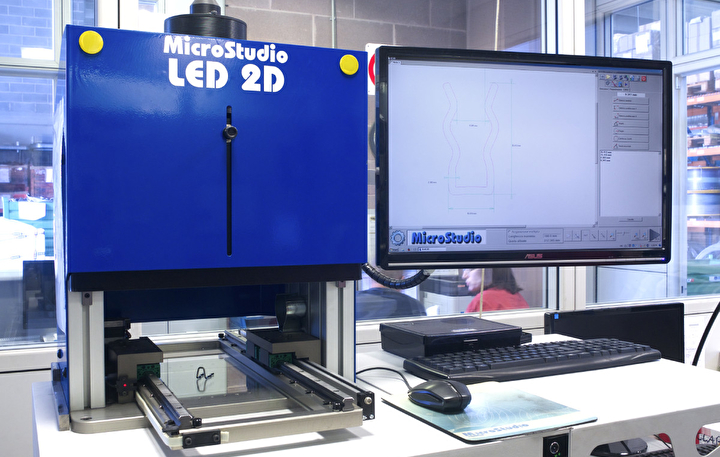

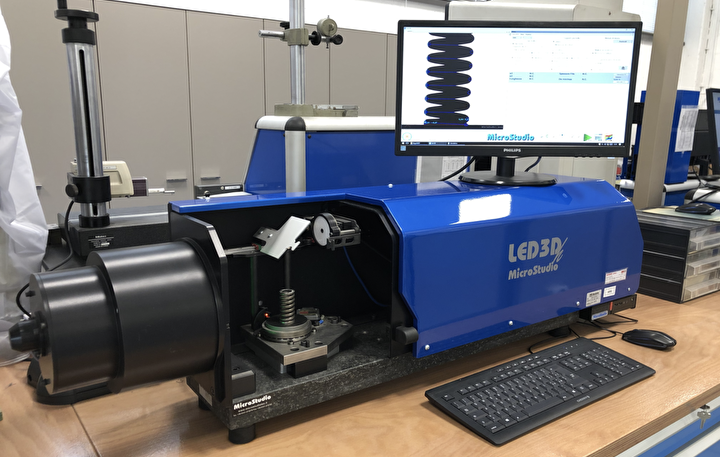

Thanks to a cutting-edge metrological laboratory, the company performs continuous controls throughout the production process. 2D and 3D LEDs, Dynamometers, Torque Gauge, Roughness Meter, Durometer , Profile Projectors, and Micrometres are available as well.

At the end of each production, a " Certificate of Conformity" of the batch produced is issued and dimensional and load surveys are provided. Upon the customer request, the company also releases the following documents: Certificate of Chemical Analysis of Raw Material, documentation ISIR (Initial Sample Inspection Report) , PPAP (Production Part Approval Process), FMEA (Process Failure Mode Effects Analysis), SPC (Statistical Process Control).